Choose the bending machine that suits you

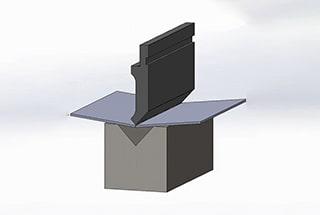

In the field of metal fabrication, press brakes play a vital role in shaping sheet metal precisely and efficiently. Whether you’re in automotive, aerospace, or industrial manufacturing, investing in the right press brake can significantly improve productivity and accuracy. In this article, we’ll explore the benefits of modern press brakes, the key features to consider, and how they can improve your workflow and increase productivity.

Find the press brake that’s right for you

When selecting a press brake machine, consider these factors:

- Tonnage Capacity – Determines the maximum bending force.

- Bending Length – Choose a machine that fits your workpiece size.

- Back Gauge System – Ensures precise positioning for repeatable bends.

- CNC Control – Allows for programmable bending sequences and reduced manual errors.

- Safety Features – Laser guards, light curtains, and emergency stops protect operators.

- Safety Features – Laser guards, light curtains, and emergency stops protect operators.

Each generation of press brakes is updated

Generation machinery: three-cylinder hydraulic press brake

It adopts a three-cylinder synchronous structure, with uniform pressure distribution, which is suitable for large workpieces and heavy-duty processing (such as thick plate bending), but the control accuracy is low, relying on mechanical synchronization and manual labor.

The second generation of machinery: digital display hydraulic press brake

Equipped with a digital display system, it can display bending parameters (such as angle and depth), requires manual intervention, and is low-cost, suitable for simple workpieces and small batch processing.

CNC hydraulic bending machine

Combined with CNC system and hydraulic technology, it has high precision, convenient operation, suitable for medium and high-end mass production, and high cost performance.

Flexible automatic bending machine

Fully automated, support automatic loading and unloading, mold change and bending, high flexibility, suitable for multi-variety, small batch customized production, high degree of intelligence, remote monitoring and data collection.

We can provide you with all the above bending machines